|

SIZE DOES MATTER! And Smaller IS Better!! Let’s Talk Profits: Producing In-Demand Aggregate Sizes With the Senya 5 Costs for raw construction materials are on the rise — sand, gravel and stone prices alone rose 7.5% within 12 months. Aggregate prices have easily doubled over the past several years and costs continue to skyrocket. Market fluctuations can be a headache, but there’s money to be saved and made, as long as you’ve got the right equipment! We’ll break down the most in-demand aggregate sizes for the construction and landscaping industries, and how the Senya 5 Portable Jaw Rock Crusher can help you cash in. Understanding Crushed Stone Grades For example, #1 stone is the largest grade and includes stones between 2 and 4 inches in diameter for use in large construction jobs and filling holes. Grade #10 is also known as screenings or dust, with stones only up to a quarter inch in diameter, and is commonly used as a fill material in pavers or concrete blocks. You can also find specialty crushed stone sizes like #57 and #67. Why Smaller Aggregate Unlocks Bigger Opportunities There is a growing demand for specialized and smaller aggregate sizes in modern construction and landscaping projects. Applications like paver bases, decorative pathways and drainage provide opportunities for greater profits, as smaller, sorted aggregates can command more premium prices compared to larger, less-processed material. Large crushers and shredders might only be able to produce larger material, meaning there’s a market for rock crushers that can produce smaller, more sought-after grades for construction and landscaping projects. Harnessing this corner of the market can unlock new revenue streams and expand your capabilities. The Most Profitable and In-Demand Aggregate Sizes The most profitable aggregate sizes include: Crush and Run, ABC (Aggregate Base Course) Stone — 1-1.5 inch We call this grade the “money size” because it’s probably the most in-demand aggregate size. Generally around 1 to 1 ½ inches in diameter, grade produces crushed, angular stones. Common applications include: • Concrete mixes. • Driveways • Drainage systems. • Base for concrete pours in foundations, concrete slab, asphalt roads Crush and Run is one of the most widely used aggregates, and it’s incredibly versatile for a variety of projects. Because this is such a popular aggregate, the opportunity for profit is almost endless. If you’ve got demo waste, you can recycle it into ABC stone to use in your own projects or sell to your competitors. #57 Stone —1/2-3/4 inch At ½ to ¾ inch, #57 stone is noticeably smaller than ABC, with more specialized applications. While not as versatile, its smaller size make it better suited for certain application as the smaller size packs better. #57 stone is used for: • Pipe bedding. • Decorative landscaping. • Driveways • Concrete mixes. • Backfill for retaining walls Producing #57 stone opens doors for greater profitability, as it’s often sold at a higher price per ton than ABC, easily costing $10-$12 more per ton. Since its applications include landscaping and decorative uses, having access to #57 stone can open the door to those more specialized finishing jobs. #2-#3 Stone — 2 to 3 inches This size stone is slightly larger in size, making it a little more robust and stronger than smaller sizes. The angular shapes and size of this size offer better stability than smaller, smoother aggregate grades. Uses for this grade stone include: • Construction Site Entrances • Road base layers. • Septic systems. • French drains. While larger than ABC and #57 grade stones, the #2-#3 stone is still a competitive aggregate option for contractors, especially for drainage and erosion control. Because it offers greater stability, it can also provide an excellent sub base for driveways and roads where smaller aggregate is layered on top. Producing material is like milling steel, it takes more processing to get the material down to the most in demand sizes. Many use Senya’s MICRO Crushers as final crushers to their larger crushers that can only produce 3-5” or larger material, or smaller sizes only as a byproduct to their first run material. Having to rerun the material to produce this smaller sizes increases the cost dramatically, and why a Senya MICRO Crusher can be so valuable. They can produce the money sizes on the first run. Of the three key marketable sizes, ABC is the most in demand at probably 55-60%, of the business, with #57 stone exploding in demand this year as availability and cost to produce this size can limit supply. The demand for this size has grown dramatically recently to 30-40% of the aggregate market. Though 2-3” size material is a small part of the market at 5-10% of the demand, don’t overlook this size as you develop your crushing business as customers for the primary sizes need this one as well. Be their one stop shop for aggregate! The Problem With Oversized Crushing Equipment Oversized crushing machines are designed to break large rocks into coarse material, typically ranging from 3 to 5 inches. They can be suitable until you need smaller, more precise aggregate sizes. Then you’re stuck paying extra or missing out on jobs. This can create a range of problems, such as: • Cost of outsourcing: Without access to machines that can create the desired aggregate sizes, you might need to turn to suppliers to source the aggregate you need. This can impact your profit margins, as suppliers may demand higher prices for smaller aggregate. • Losing out on jobs: If your rock crusher can only produce larger aggregate, you may not be able to work on certain jobs, impacting your profitability. • Transportation costs: Purchasing aggregate from a quarry or other supplier incurs additional hidden costs — specifically the transportation of materials from the point of purchase to the jobsite. |

Introducing the Senya 5:

Your Aggregate Profit Center

The Senya 5 from Senya Crushers isn’t just a machine — it’s a next-generation MICRO jaw crushing plant. Take control of your aggregate production with a crusher specifically built for small to midsized contractors who need versatility and power in a compact, portable package. Our MICRO plants give you the ability to process, recycle and produce aggregate in a way that you simply won’t find anywhere else in the industry. Pull with a pickup, drop the legs and be crushing in 10 minutes, and crank out 200-400+ tons per day!

5 Reasons to Choose the Senya 5

Here’s why contractors are turning to the Senya 5 for aggregate production:

1. Precision Sizing for Top Dollar

The Senya 5’s adjustable settings allow for the precise production of in-demand aggregate sizes. Take advantage of the growing demand for smaller aggregate with a machine purpose-built for smaller stone grades between 3/8 inch and 3 inches. There’s no need to haul or load large demolition materials, so the Senya 5 also saves on transportation costs.

2. Compact Power for any Jobsite

At Senya Crushers, we set out to manufacture a machine that combines the power of larger crushing systems while prioritizing portability and cost efficiency. The Senya 5 can be towed with a standard pickup and is road legal, meaning there’s no need to hire special vehicles to haul machinery or materials to and from your jobsites.

3. Unmatched Efficiency and Reliability

Powered by a self-contained Yanmar engine 4TNV98C-GGE diesel generator, the Senya 5 delivers exceptional performance in the most demanding conditions. Its capacity of 50 tons per hour (tph) — and up to 500 tons per day — makes it a quarry on wheels. Our pioneer diesel-over-electric system provides significant power at a lower cost, and this workhorse can run all day on about $50 of fuel.

4. Versatility

Whether you’re recycling construction waste or performing a landscaping job, the Senya 5 is up to the task. Designed with moving and fixed opposing jaw plates, this machine can break down a range of materials into preset grades — perfect to target those in-demand aggregate sizes.

Senya 5 can handle just about anything you throw its way, including:

• Concrete

• Granite and granite countertop scrap

• River rock

• Glass

• Limestone

• Asphalt

5. Free Aggregate for Life

Your Senya 5 can easily pay for itself in a very short time and reasonably low volumes of production. At only 20 truckloads per month on the demolition disposal and aggregate purchase sides of the equation, THE SENYA PAYS FOR ITSELF IN LESS THAN 4 MONTHS! Use your own figures in our cashflow calculator on the Senyacrushers.com web site.

With the cost-saving opportunities, increased capabilities and convenience of a portable rock crusher, there’s almost no downside to investing in this machine. It’s a long-term solution that will help you pivot quickly in response to changing market demands and environmental regulations.

SCR$$NED IS GR$$N

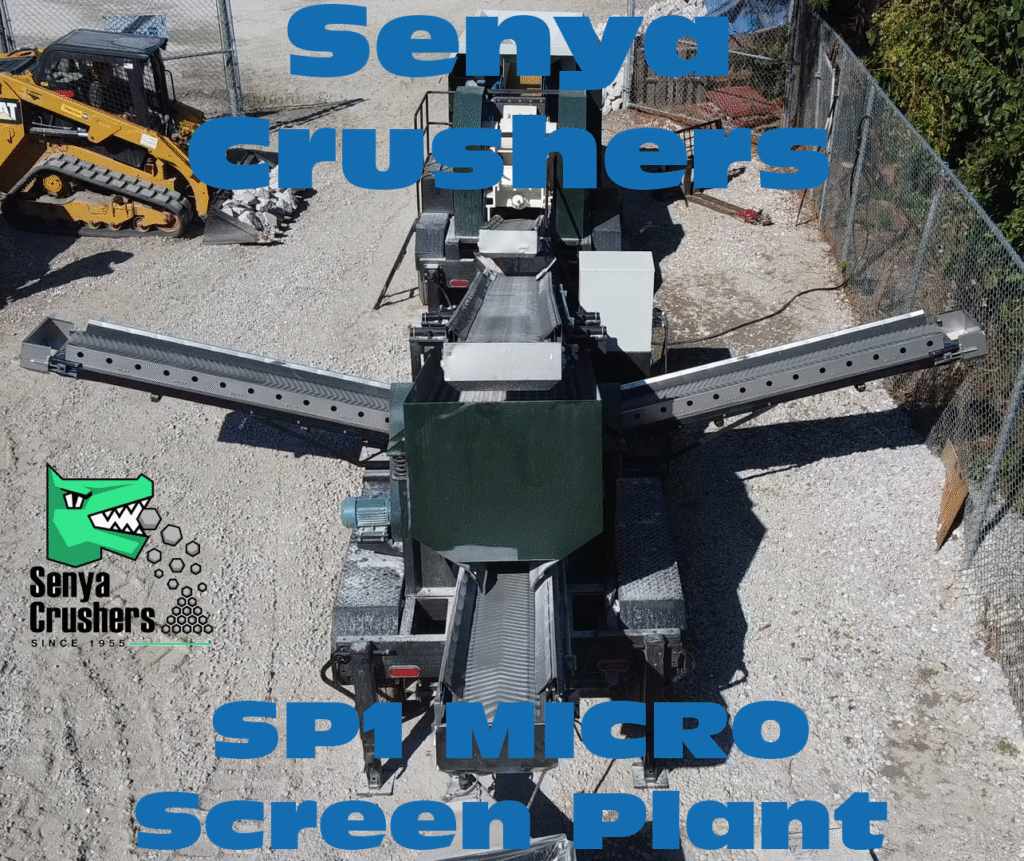

You can produce all three of the most in demand sizes simultaneously and sort and grade the sizes with Senya’s MICRO Screen Plant. The distribution of the percentage of the sizes depends on the jaw gap setting your crusher, simply adjust to your target size or set to produce similar amounts of all sizes at the same time depending on your demand for aggregate. Screened, graded to size material is worth considerably more as it costs to produce it, usually over $10 more per ton! Be sure to take advantage of Senya’s MICRO Screen Plant capabilities to MAXIMIZE your PROFITS!!

Take advantage of 2025 tax and finance savings now!

Deduct 100% of the cost of your crusher on this years tax return and let’s Uncle Sam pay for 1/3 of your crusher! Our strong finance partner, ElmBlue Equipment Finance loves to loan money on our machinery because they know it’s a great loan because our machinery makes TONS of $$$$!

They even have a special currently running with ZERO Downpayment and deferred payments for up to SIX MONTHS! Take delivery of your crusher now, crush all winter during the slower months, and be AGGREGATE READY for Spring 2026, ALL BEFORE YOU MAKE YOUR FIRST PAYMENT!!

Click on the picture below to start your online application with Mike, our dedicated account specialist, his contact details below as well. It literally only takes about 5 minutes, rates are great these days, SEE WHAT THEY CAN OFFER YOU NOW!

| Start Crushing It NOW With Senya Crushers with NO PAYMENTS UNTIL SPRING, BE AGGEGATE READY IN SPRING 2026! If you’re serious about starting a crusher business, Senya Crushers is your one stop shop to get started. We offer revolutionary MICRO Aggregate Processing equipment designed specifically for small to midsized contractors. Our full MICRO Plant lineup delivers the power of a full-scale aggregate setup in a portable package of the crusher, screen plant, and stacker conveyor. Senya Crushers’ USA made, titled, and VIN’d trailer-ready, American-made products are ready to go as soon as you hook them up to your truck. We don’t just sell machines — we help build businesses. Every customer gets in-person, on-site training. We also provide lifetime DIRECT support from an expert team, including our owner who personally designed these machines, is active daily in the business, and loves to get on-site to visit our customers. Our sales manager especially loves helping our customers get started in the crushing business and can be a tremendous help by sharing what we have seen drive impressive results and stellar growth with our other customers. Spend some time on our NEWS page, there is a wealth of invaluable information to those getting in the crushing business with many articles directed to new startups, how to quote jobs, and the possibilities when you have the ability to crush. THEN Reach out to us online to start your crushing business or CALL US today! We’d love to discuss your possibilities and how our equipment can help you realize your plan to make a lot of money “Bustin’ Rocks” with Senya Crushers!! |