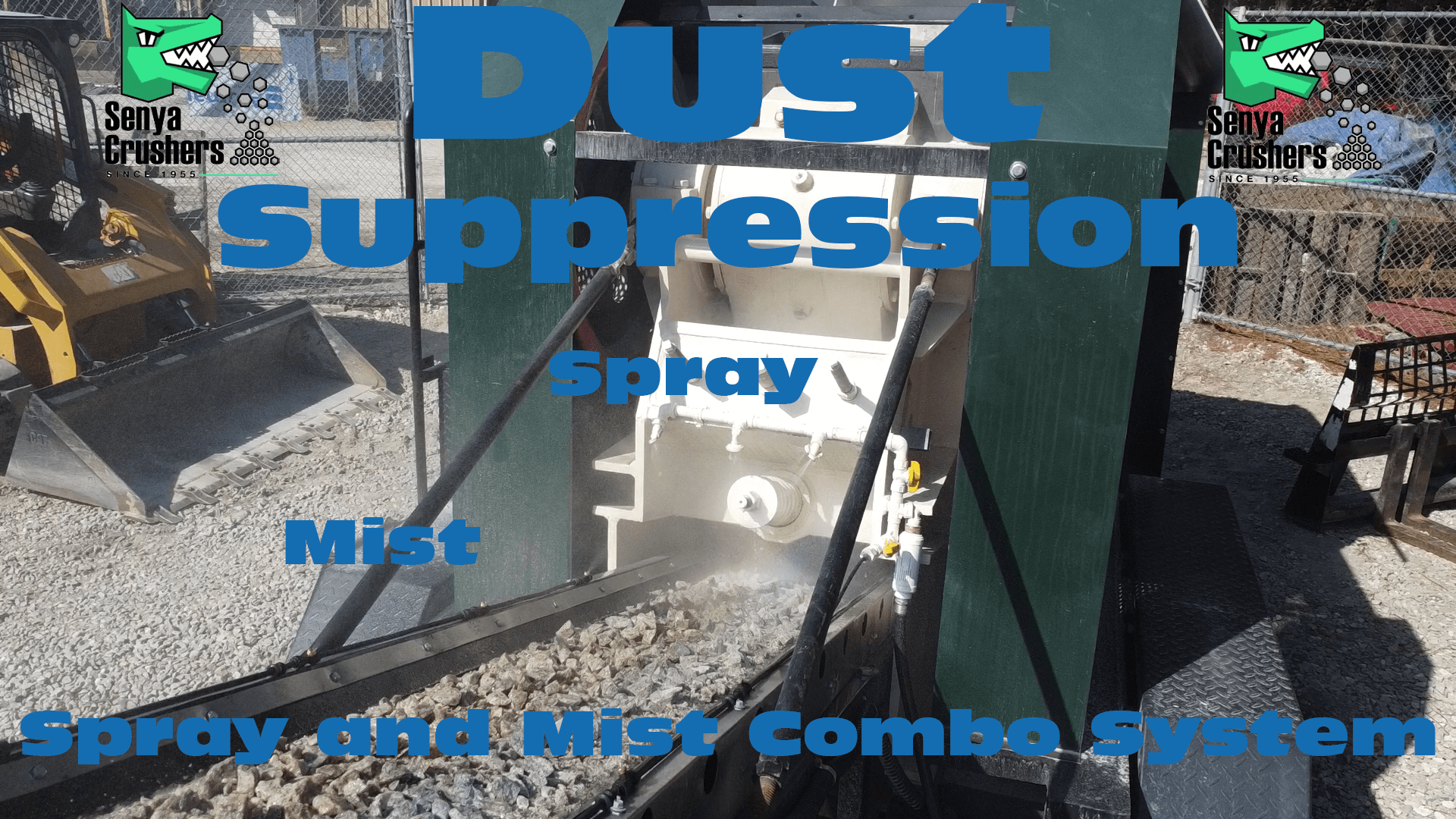

MADE IN USA

Senya Crushers is proud to deliver machinery and products 100% made in the USA. Our MICRO Crushers are manufactured in Raleigh, North Carolina, and distributed nationwide. Our homegrown manufacturing means we offer first-class products and upgrades.

We continue to push the envelope as world-class and industry-leading pioneers in the MICRO Crushing category in aggregate processing engineering. We provide cutting-edge technology and unmatched results.