Whether you’re in the construction, agriculture, industrial recycling or infrastructure industry, a rock crusher will undoubtedly benefit your operations. Still, you may have questions about the long-term expenses and benefits of equipment rental compared to ownership.

We’ll walk you through the ins and outs of renting versus buying so you have a rock-solid understanding of the best option for your business.

Factors to Consider

Considering the following factors and questions is a solid starting point.

- Usage frequency and project duration: How often will you use the rock crusher? Are you looking for equipment for a one-and-done project or a long-term solution? Will you have future projects where the crusher can be of benefit? Are there other job types you could pursue with the ability to crush for yourself?

- Demolition disposal costs: Are you doing demolition? What are your disposal costs? How many tons/truckloads per month do you average? How much does it cost you to haul away your demolition? What are your tipping fees? Are those fees increasing?

- Aggregate purchase costs: How much aggregate are you buying in an average month? How many tons or truckloads do you average? What’s the cost per ton or truckload? What are the delivery fees? Are these costs increasing?

- Demolition and aggregate transportation costs: Up to half the cost of either can be the transportation of the material. How far away is the dump or your aggregate supplier? Can you recycle your demolition and use it on site as base or fill? Those saving can be tremendous if so.

- Budget: Is it feasible for you to invest in new equipment and pay the upfront costs if not financing? Financing can eliminate significant up from costs. Volume of demo disposal or aggregate purchases and their cost elimination can easily cover a monthly payment at minimal volumes. Will rental expenses add up over time and become less cost-effective?

- Storage limitations: Do you have a place to store equipment, or will renting save space?

- Maintenance needs: Can you afford to invest time and money into maintaining new equipment? Consider the latest diesel of electric technology equipment almost eliminating maintenance costs. These new innovations make a dramatic difference in these costs.

- Technology features: Do you want access to the latest technology with less upfront cost as well as long term maintenance costs?

- Customization: Could you benefit from the customization options that come with purchasing equipment? Do you need metals removal to remove rebar and wire or other metals? Do you need dust suppression systems to minimize this aspect of crushing in some climates and weather, especially in residential or metro areas? Does wireless remote control operation offer a benefit for smaller crusher crew operations?

- Potential resale value: Are you interested in reselling the equipment down the line? How well does the machinery you are considering hold its value? Is it feasible to purchase a MICRO Crusher for a single job even? Resale values often make this the case on jobs as small at 1500-2000 tons of material, only 75-100 truckloads on a single job.

- Future needs: Will you need to own a rock crusher someday as your business grows? How can you expand your business and profitability by owning your own crusher? Have you considered the other revenue streams possible with a crusher such as the decorative rock business, glass or granite countertop recycling, concrete washout recycling, landfill contract crushing? The possibilities are endless.

- Transportation to the worksite: How will you get the equipment to the site? Check rental mobilization fees, or will you need a tractor-trailer for new equipment? Does a portable crusher on its own towable chassis make sense? Would this portability be of benefit across several job sites you are working on at once?

Advantages of Renting versus Owning a Rock Crusher

Renting a rock crusher offers several benefits.

- Cost-effectiveness for short-term projects: A new rock crusher comes with a significant investment, which you can minimize often with a rental. This benefit is most applicable when you’re searching for equipment to complete a shorter project or smaller project.

- Maintenance costs: The rental center sometimes takes care of maintenance, which can be a tremendous advantage — larger rock crushers undergo lots of wear and tear. Be sure to ask about extra “wear and tear” fees in your quote, they can add up.

- Easy transportation to the worksite: When the rental company handles transportation, you have one less thing on your plate. Some companies may charge significant mobilization fees, but this benefit is all about convenience. However, it probably shouldn’t be the straw that breaks the camel’s back — when you invest in a portable crusher, you can tow it with a dump truck or large pickup.

- Access to the latest tech: Renting equipment may give you access to the latest in rock-crushing technology without the steep upfront cost. This may or may not be the case depending on the equipment. Be sure to understand the technology of the equipment you are considering renting.

Drawbacks of Renting versus Owning Equipment

There are also some downsides to renting.

- Limited availability: Changes in demand may make finding equipment challenging, especially if you’re in the market for something specific. This is especially true of smaller crushing projects as most large crusher rental companies require a minimum of 5K-10K tons to justify the mobilization of their large equipment on site. The minimum to rent a crusher is usually a minimum of $20K, and mobilization fees, wear and tear fees, cost per ton fees, and parts fees can easily push the quote to over $30K for even the smallest jobs.

- Less affordable for long-term projects: Though renting equipment may be a logical solution for short-term projects, it’s not generally the best choice for projects with a longer duration. In these cases, rental costs may exceed the cost of purchasing a machine outright.

- Less flexibility: Reselling or loaning out equipment isn’t an option for renters.

- Fewer customization options: While customizations can boost project efficiency, you usually cannot alter rental equipment.

- Higher Operation Costs of older technologies: Many rental companies utilize older equipment with considerable operation and maintenance costs. Older equipment has a much greater chance of being down as they require more service and maintenance.

Pros and Cons of Buying a Rock Crusher

You can enjoy the following benefits when you own a rock crusher.

- Immediate availability: You won’t have to wait for rental availability to perfectly align with your project deadlines. When you purchase a machine, it’s ready whenever you need it.

- Cost-effective for longer projects: The longer you need a rock crusher, the more economical purchasing one becomes.

- Customizable to fit your needs: You can tailor purchased equipment to suit specific needs, enhancing efficiency.

- Flexibility: Owning equipment frees you to loan it to other companies or resell it later.

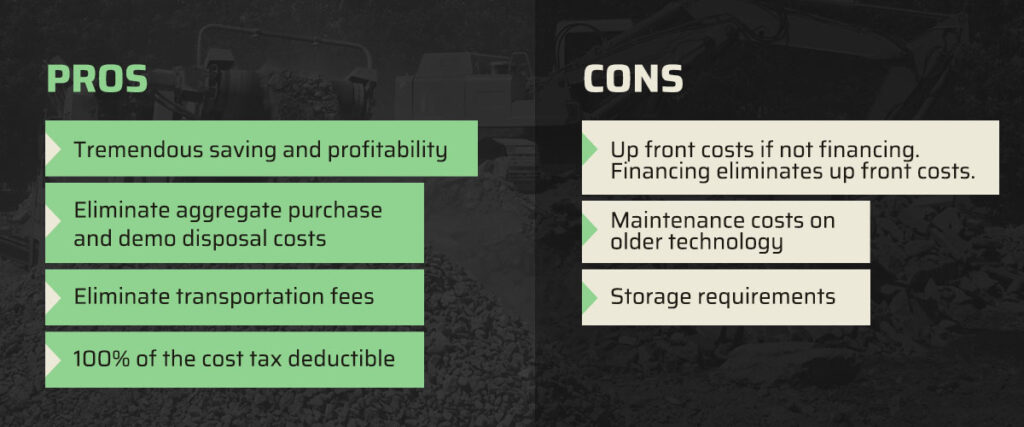

Despite the advantages, there can be some downsides to purchasing a rock crusher.

- Upfront costs if not financing: The substantial initial investment may not be feasible for all budgets or if you are not able to finance the equipment.

- Maintenance investment: Purchasing equipment leaves you responsible for maintenance and repairs, adding to your total ownership cost over time. Historically this has been the case with direct drive engine machines and those that utilize hydraulics for jaw adjustment or tracks for portability. The latest diesel over electric technologies have revolutionized this aspect of crushing maintenance making this a non-issue with machines utilizing those technologies.

- Storage requirements: You’ll also have to find a place to store your new equipment, which can be challenging if you have limited space.

Tips to Help You Decide

Still feeling torn? These final tips can help solidify your decision:

- Research rental and for-purchase models and how their features compare to your project needs.

- Assess how often you’ll use the machine and whether your needs are short- or long-term.

- Compare the total costs — including insurance, fuel, and maintenance — to get a fuller picture.

- Evaluate your available storage space.

- Determine whether you have the time and budget to handle repairs yourself.

- Consider your future needs and how owning this equipment will benefit operations.

- Most importantly, make the cashflow calculation starting with the volume of material and demolition disposal and aggregate purchase costs. Senya Crushers has an online calculator which lets you use your own numbers to “really put a pencil to it”. The results can be staggering, even to those knowing the benefits of crushing for yourself. Access their online calculator here: Senya Crushers Cashflow Savings Calculator

The Bottom Line — Buying vs. Renting Rock Crushers

While renting equipment can mean a lower upfront investment and possibly reduce the maintenance burden, owning equipment is always more cost-effective for long-term projects, offers plenty of flexibility and allows you to customize it according to your needs. Your decision depends on which benefits you prioritize. As demolition disposal/tipping fees and aggregate purchase and transportation fees continue to skyrocket, there are very few contractors or jobs that cannot benefit tremendously from owning a small, affordable, and highly portable crusher.

Ultra-Portable MICRO Rock Crushers From Senya Crushers

If you are considering purchasing a rock crusher but think your business is not large enough to justify it, let us introduce the Senya 5 Portable Jaw Rock Crusher. Senya Crushers has honed the MICRO Crusher concept to perfection with the only small crusher utilizing a USA-made, titled and VIN’d portable chassis, triple/triple air filtration, and most importantly-the diesel over electric configuration utilizing a USA made, serviced, and warrantied Yanmar powered 40KW Diesel generator enclosed inside the machine. There’s plenty of power left over for a ‘plug and crush” screen plant sorting three sizes, three MICRO Conveyor/stackers, and even a step-down transformer providing 20 amps of 220v or 30 amps of 110v on-site power as an upgrade option. There’s also the magnetic metals removal conveyor and dust suppression system option as well. This MICRO rock crusher is easily towable with your pickup truck, and its small size doesn’t mean compromised functionality — at up to 50 tons per hour the Senya 5 can easily crank out 300-500 tons/15-25 truckloads per day!

Plus, the lack of hydraulics or diesel exhaust fluids (the generator is just below the size DEF fluid is required) means maintenance and operating costs are negligible. The Senya 5’s diesel generator runs all day on $40 worth of fuel. With the Senya SP1 MICRO Screen Plant and the S2318 MICRO Conveyor/Stacker, It’s a portable quarry on wheels!

Revolutionize Your Bottom Line With Senya Crushers

Interested in learning more about getting started with crushing? Check out some of our other helpful resources: